four-point bending test|4 point bending test standard : wholesalers What is the 4 point bend test ASTM? The ASTM D6272 is the standard for the 4-point bend test. This test measures the flexural properties of plastics, including composite materials. WEB27 de dez. de 2023 · Explore. Five Nights at Freddy's. Community. ALL POSTS. Dittophobia. Wiki Article. Dittophobia is the third story of Tales from the Pizzaplex 8: .

{plog:ftitle_list}

• She Was Pretty official MBC website (in Korean)• She Was Pretty at MBC Global Media• She Was Pretty at IMDb• She Was Pretty at HanCinema Ver mais

The 3-point bending test is slightly easier to conduct and analyze. The cracking and failure in 3-point bending are well defined by one point on the specimen, under the point load. This can be easier identified than in the 4 .Three and four point bend tests are commonly used to determine the flexural strength of a specimen. When a specimen is bent, it experiences a range of stresses across its depth. At .3-point bending test: It produces its peak stress at the material mid-point and reduced stress elsewhere. 4-point bending test: It produces peak stresses along an extended region of the .The 4-point bend is a popular "scientific" adhesion test. The two forms discussed here share the basics: An elastic substrate, modulus E 2, thickness H sits on two points equidistant from the middle of the sample. A force F is applied from the .

What is the 4 point bend test ASTM? The ASTM D6272 is the standard for the 4-point bend test. This test measures the flexural properties of plastics, including composite materials. Four-point bending test are widely used to investigate the strength and toughness of FRC [13], [14].The flexural toughness of FRC has became a key parameter in engineering design and construction inspection [13], [14], [15].American Society for Testing and Materials (ASTM) C 1018 [13] and Japan Society of Civil Engineers (JSCE) SF-4 [14] testing methods .

Scope: The Flexural test ASTM D6272 measures the force required to bend a plastic beam under a four point loading system. The test method is used for reinforced or unreinforced materials including high modulus composites and for materials that do not fail within the limits of ASTM D790 (a three point loading test).Mach-1 – 3-point or 4-point Bending Test MA056-SOP11-D v1 BMMT CC#2016-001 BMMT QF4.02.01 v1 CONFIDENTIAL - UNCONTROLLED UNLESS OTHERWISE SIGNED AND/OR STAMPED Page 7 / 9 Note: Since the loading pin(s) and the metal piece need to be in contact (metal on metal contact), it is important to use a very low approach speed (Find Contact .

lab semi-auto chemistry analyzer mslba50

Four-Point Test. A four-point bending test is very similar to a three-point test, But except the load is applied at two points simultaneously, again towards the center of the sample. It’s easiest to calculate the flexural strength when one load or force is applied one-third of the way between the supports and the second is applied two-thirds .Four Point Bending. In this lab, a Four-Point Bend Test is performed on ABS plastic beams from the PASCO Structures System and the Flexural Elastic Modulus for the material is calculated. Grade Level: College. Subject: Engineering. Student .The test can be conducted in different configurations, such as three-point or four-point bending, to simulate different loading conditions. Flexural testing is governed by specific international standards like ASTM D790 and ISO 178, ensuring consistency in procedures and results across different laboratories.The arrangement of the testing apparatus (three-point or four-point bend, distance between supports, etc.) also influences the calculation of the beam mechanics. For more in-depth detail, click the links below to see step-by-step calculations that are made during bend tests: Example 1: Rectangular Specimen in Three Point Bending Test

Bending test is used to determine the tensile strength of brittle materials that are generally difficult to test in uniaxial tension due to cracking in the grips. The most common bending tests include cantilever, 3- and 4-point bending, and G-torsion as shown in Fig. 3.9.We wish to find the equation of the deflection curve for a simply-supported beam loaded in symmetric four-point bending as shown in Figure 7. From Figure 6, the deflection of a beam with a single load at a distance \(a\) from the left end is \(\delta (x) = \dfrac{Pb}{6LEI} [\dfrac{L}{b} \langle x - a \rangle^3 - x^3 + (L^2 - b^2) x]\). Our .Four-Point Bending. A Four-Point Bend Test is performed on plastic beams as shown in Figure 1. As a downward force (F) is applied in the middle of the beam, the flex (Δx) is recorded. The ratio (F/Δx) is the effective stiffness of the length of beam being tested, and is measured directly from the slope of the F vs. Δx graph. .In the 4-point bending test, the checking fixture differs from the 3-point bending test only in its test punch. Instead of the single punch applying force in the center, a double punch is used. There is a constant bending moment in the area between the two upper pressure points. Transverse forces do not occur in this area.

Jenis-jenis Uji Bending. Pengujian bending memilikidua jenis atau cara pengujian, diantaranya : Pengujian Dua Titik (Three-Point Bending): Metode ini merupakan salah satu metode yang paling umum digunakan dalam uji bending. Pada uji ini, beban dipasangkan pada bagian tengah sampel bahan, sedangkan dua titik dukungan berada di kedua ujungnya.

Bend Testing Equipment Guide; 3 and 4 Point Bend Testing of Semiconductor Devices; Fiber-Reinforced Concrete Testing: Design Changes in ASTM C1609 Equipment; Performing ASTM C1609 on an ADMET eXpert 2655 Universal Testing Machine; How to Perform an ASTM D790 Plastic Flexural 3 Point Bend Test; How to Perform a 3 Point Bend Test on a Universal .

Bend Test: The UTM is then used to apply a gradually increasing load at the center of the specimen (for three-point bending), or at two points for four-point bending. The software records the force applied and the displacement of the mandrel.The emphasis in this document is on the methodology of the four-point . bend test. The context . of the test results for service application is the responsibility of the end-user. and is . discussed in . NACE MR0175/ISO (1) 15156. 1-3 _____ Section 2: Principle . 2.1 The four-point bend test is a constant displacement test that is performed by . The four point bending test described in EN1288-3 (Fig. 1) consists of a 1100 mm by 360 mm glass plate that is held by two support rollers spaced 1000 mm apart. Two bending rollers spaced 200 mm apart press on .This test setup includes a 3400 Series test system with a 3-point bend fixture and no extensometer, meaning that strain in this case must be measured by crosshead displacement (Type 1 testing). Whenever strain is measured via .

Analysis of four point bending. The values obtained in this example are dependent on the initial spacing of the applied loads. Also, the shear and moment dia.

Wood and composites are most commonly tested with the 4-point bend test. The 4-point test requires a deflectometer to accurately measure specimen deflection at the center of the support span. Test results include flexural strength and flexural modulus. Brittle Materials. When a 3-point bend test is done on a brittle material like ceramic or .Figure 1 gives the plans for the 4-point bend test apparatus. The dial indicator is below the beam in the test setup as shown in Figure 2. This results in a small upward force due to the spring associated with the dial indicator. The total cost for a setup is given in Table 2. Table 2. Equipment needed for the 4-point bend test. Components .The 4-point bend is a popular "scientific" adhesion test. The two forms discussed here share the basics: An elastic substrate, modulus E 2, thickness H sits on two points equidistant from the middle of the sample ; A force F is applied from the top, at a distance L from the two points

Using the static analysis of ANSYS 19, longitudinal, radial, and tangential beam specimens of spruce, Scots pine, and beech were subjected to stress and strain analysis under symmetrical four-point bending and asymmetrical four-point bending. The effects of wood grain on the surface of the specimen and its stress properties on the transverse and .

FOUR POINT BENDING TEST 1. Bending Theory for a Rectangular Beam 1.1 General Theory The deflections due to shear V s and due to bending V b of a rectangular beam, which is vertical loaded along the beam by a force Q(x,t) are governed by two differential equations (assuming homogenous material).The three-point bending flexural test provides values for the modulus of elasticity in bending, flexural stress , flexural strain and the flexural stress–strain response of the material. This test is performed on a universal testing machine (tensile testing machine or tensile tester) with a three-point or four-point bend fixture. .

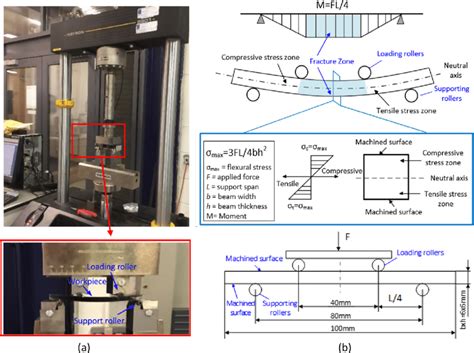

The three standard bending strength tests are the cantilever beam bend test, the three-point bend test, and the four-point bend test. European Standard EN 12384 specifies a bend test to determine the modulus of elasticity in bending. Japanese Industrial Standard JIS 3130 specifies two tests to determine the elastic limit of spring plate or . Three-point (TPBT) and four-point (FPBT) bending tests are two common methods for investigating the flexural properties of materials. Shear stress occurs on the fracture cross-section (y-axis in Fig. 2) of the beam specimen in the TPBT, while the fracture cross-section of the beam specimen in the FPBT is in a pure bending state without shear stress.The experimental setup (Figure 1) of our four-point flexural bending test and the testing procedure is based on DIN EN 843-1. From the recorded bending force- and deflection data, the stress-strain curve of the samples can be determined. Figure 1 left: schematic picture of the four-point flexual test: 1: Support-roll, parallel to sample direct .

four point bending test setup

WEBVOTALHADA - Simplificando os Realities da Vida. BBB, A Fazenda, Masterchef, Top Chef, Mestre do Sabor, Power Couple, O Aprendiz e mais. Enquetes e pesquisas no site do Votalhada.

four-point bending test|4 point bending test standard